Tesla to Convert Fremont Plant for Mass Production of Optimus

Tesla CEO Elon Musk said the company plans to convert its Fremont, California factory to produce Optimus humanoid robots, marking one of the most concrete manufacturing commitments yet for a general purpose humanoid platform. The announcement was reported by The Daily Caller and follows several years of internal development and public demonstrations of the Optimus system.

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

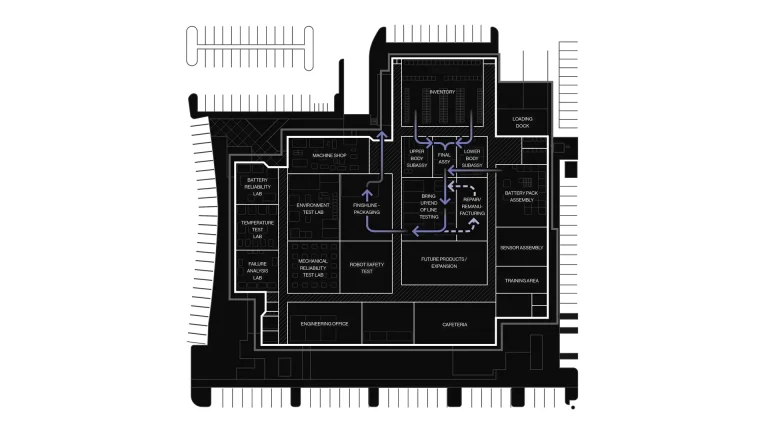

From vehicle production to humanoid robots

According to the report, Tesla will discontinue production of the Model S and Model X at the Fremont site and retool the facility for Optimus manufacturing. Fremont has historically served as a core automotive plant for Tesla, making the shift notable in scale and symbolic importance.

If implemented as described, the move would position Tesla among a small group of companies attempting high volume production of humanoid robots rather than limited pilot runs or lab scale builds.

Optimus platform status

Optimus is Tesla’s bipedal humanoid robot designed to operate in human environments and perform manual tasks. Public demonstrations to date have shown walking, object manipulation, and basic task execution, primarily in controlled settings.

Tesla has previously stated that early Optimus units would be deployed internally for factory tasks before external sales. The Fremont conversion suggests a longer term intent to scale beyond internal use, although specific timelines and output targets were not detailed in the report.

Manufacturing implications

Repurposing an automotive factory for humanoid robots raises several technical and operational questions:

- Whether existing vehicle assembly lines can be adapted for humanoid form factors and actuator integration

- How Tesla plans to source and produce key components such as electric actuators, hands, and onboard compute at scale

- What level of automation versus manual assembly will be used in early production phases

No information was provided on regulatory considerations, workforce changes, or safety certification processes for commercial humanoid deployment.

What remains unknown

The announcement does not include production volumes, unit cost targets, or a firm schedule for commercial availability. It also remains unclear whether Fremont will be dedicated exclusively to Optimus or operate as a mixed use facility during the transition.

For the humanoid robotics sector, the key signal is not immediate availability but Tesla’s apparent willingness to commit major manufacturing infrastructure to a humanoid platform. Execution details will determine whether this becomes a turning point or remains an aspirational shift.