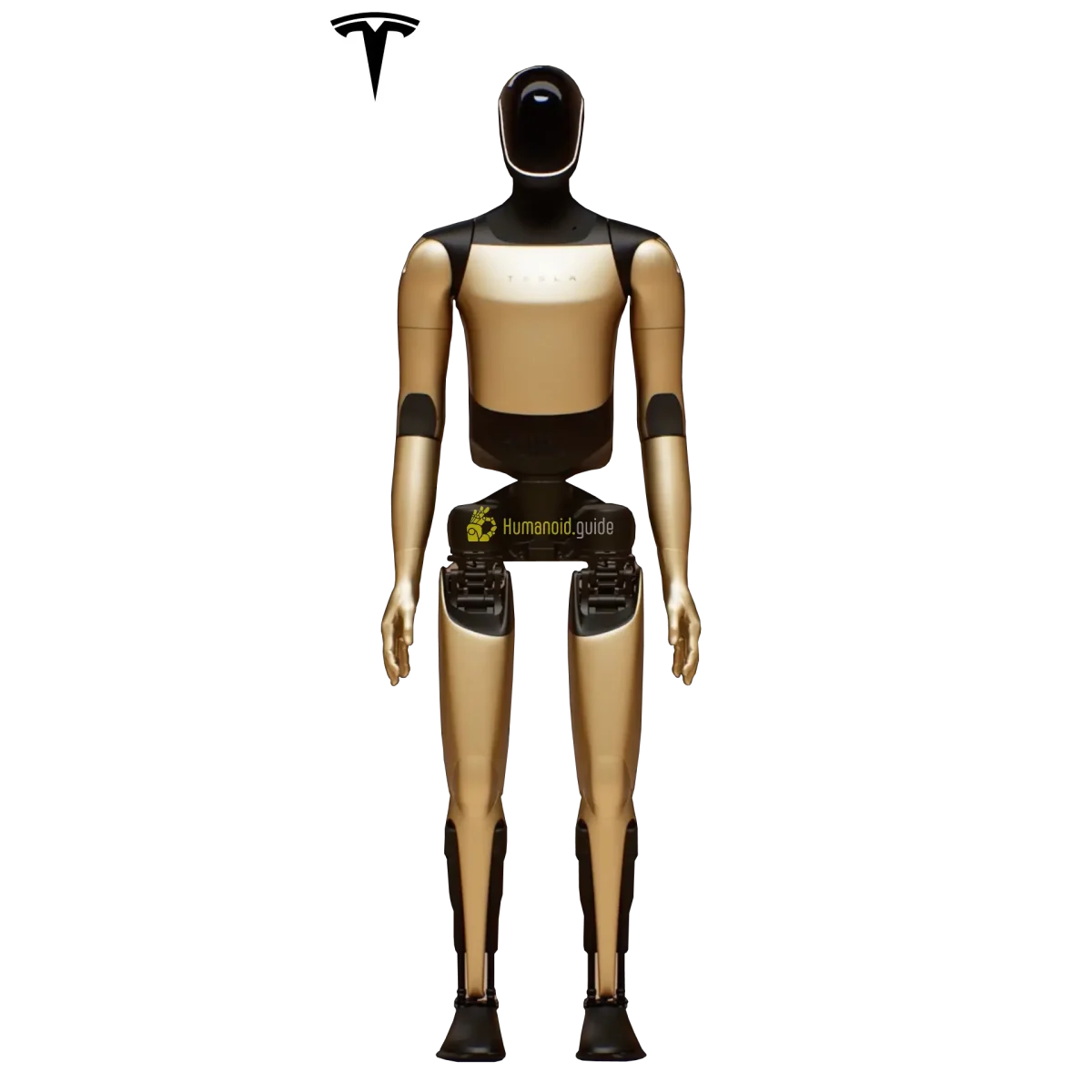

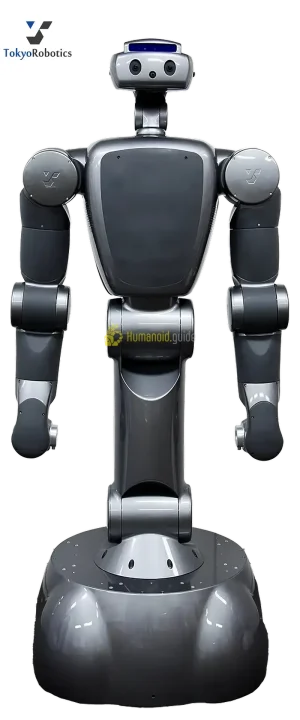

OPTIMUS V2.5

$ 45 000

Tesla Optimus v2.5 is the mid-prototype upgrade is to test the Electronics, Motors and AI systems for the new production version 3 coming in Q1 2026 and also to completely automate the factory production line for V3 robot to full scale 1M robots mass production a year to bring the cost down to only 20,000 $ per robot. Right now the Optimus v2.5 is produced at Tesla Fremont factory, California by human workers.

Skill Score

9

9Specifications and details:

| Availability | Prototype |

|---|---|

| Nationality | US |

| Website | https://www.tesla.com/en_in/AI |

| Degrees of freedom, overall | 65 |

| Degrees of freedom, hands | 22 |

| Height [cm] | 176.5 |

| Max speed (km/h) | 14 |

| Strength [kg] | 20 |

| Weight [kg] | 55 |

| Runtime pr charge (hours) | 4 |

| Safe with humans | Yes |

| CPU/GPU | AI4 & AI5 CHIP |

| Ingress protection | N/A |

| Camera resolution | 8 MP |

| Connectivity | WiFi |

| Operating system | TESLA FSD ROBOT VERSION |

| LLM integration | XAI GROK |

| Latency glass to action | N/A |

| Motor tech | N/A |

| Gear tech | N/A |

| Main structural material | N/A |

| Number of fingers | 5 per hand |

| Main market | Consumer home use, domestic assistance, Industrial automation, logistics, Manufacturing |

| H.G skill score | N/A |

| Verified | Verified |

| Walking Speed [km/h] | 8 |

| Shipping Size | N/A |

| Manufacturer | Tesla, Inc. |

Description

Tesla Optimus V2.5 represents a major step forward in Tesla’s humanoid robotics program. Designed as a mid-prototype, it helps Tesla validate key systems before full production. Rather than aiming for consumer release, this version focuses on learning, refinement, and scale preparation. As a result, Optimus V2.5 bridges the gap between experimentation and mass deployment.

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Unlike earlier iterations, this model operates reliably in complex human environments. It walks, runs, climbs stairs, and recovers from falls with confidence. Moreover, it navigates obstacles smoothly and adapts to changing surroundings. These abilities allow the robot to function naturally alongside people, without constant supervision.

Optimus V2.5 also shows strong manipulation skills in everyday and industrial tasks. For example, it can sort goods, assemble products, and manage household chores like folding clothes or handling dishwashers. In addition, its dexterous hands support precise movements needed in factories and logistics centers. This versatility highlights Tesla’s focus on real-world usefulness rather than demonstrations.

The humanoid market is a maze

Buy-a-Humanoid™

Get the right humanoid guaranteed.

Most importantly, Tesla uses Optimus V2.5 to prepare for large-scale automation. The robot is currently built by human workers at the Fremont factory in California. However, Tesla plans to fully automate production with the upcoming Optimus V3. Consequently, this shift aims to reach up to one million robots per year and reduce the long-term cost dramatically.

Download the Humanoid Robot Market Report here

https://www.tesla.com/en_in/AI