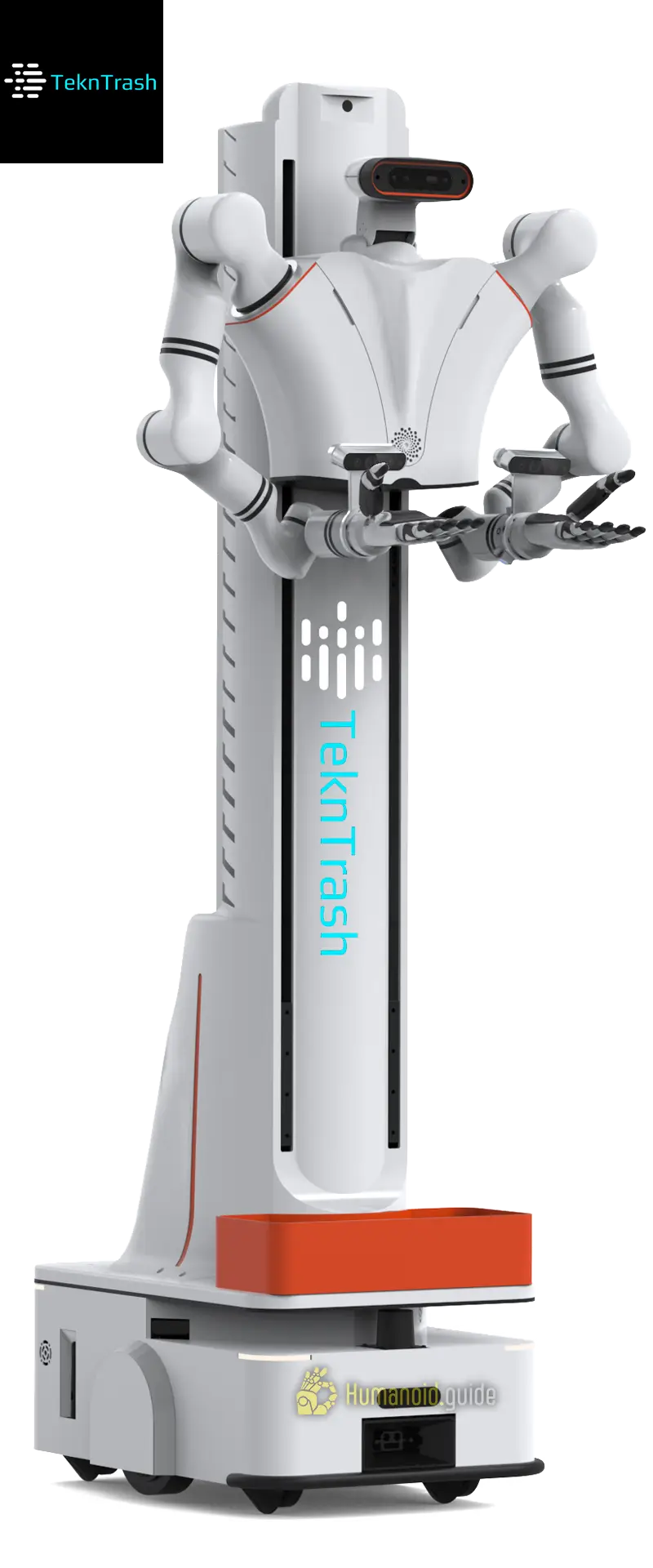

ALPHA

$ 55 000

ALPHA, developed by TeknTrash, is a humanoid robot designed to transform waste handling by automating repetitive, unsafe tasks in recycling facilities. With advanced AI, 6‑DOF arms, 3D vision, and cloud connectivity, it can sort, lift, and navigate autonomously to increase efficiency and reduce contamination in waste streams.

Skill Score

2

2Specifications and details:

| Availability | Prototype |

|---|---|

| Nationality | UK |

| Website | https://www.tekntrash.com/ |

| Degrees of freedom, overall | 13 |

| Degrees of freedom, hands | 2 |

| Height [cm] | 200 |

| Manipulation performance | 2 |

| Navigation performance | 2 |

| Max speed (km/h) | 0.9 |

| Strength [kg] | 5 |

| Weight [kg] | 90 |

| Runtime pr charge (hours) | 7 |

| Safe with humans | Yes |

| CPU/GPU | Nvidia Orin AGX 64 |

| Ingress protection | IP32 |

| Camera resolution | 640×480 |

| Connectivity | WiFi |

| Operating system | Ubuntu 24 |

| LLM integration | deepseek |

| Latency glass to action | 20 ms |

| Motor tech | Realman |

| Gear tech | Realman |

| Main structural material | Aluminum, Plastic |

| Number of fingers | 4 |

| Main market | Recycling |

| H.G skill score | N/A |

| Verified | Not verified |

| Walking Speed [km/h] | N/A |

| Shipping Size | N/A |

| Color | N/A |

| Manufacturer | N/A |

Description

Waste handling is dirty, repetitive, and dangerous work — and TeknTrash believes it’s time for a change. That’s why they’ve developed ALPHA, a humanoid robot designed to work in recycling plants and other waste-processing environments. Unlike traditional robots, ALPHA isn’t just another conveyor picker — it’s a mobile, collaborative system capable of navigating, grasping, lifting, and learning.

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

ALPHA features dual 6-DOF robotic arms, each equipped with grippers and 3D vision, allowing for up to 5 kg of total lift. The base supports autonomous navigation, dynamic obstacle avoidance, and real-time positioning via deep-learning sensors, LiDAR, ultrasonic sensors, and IMUs. The adjustable lifting column reaches a maximum height of 2 meters to optimize reach on conveyor belts and waste bins.

At its core, ALPHA runs on an NVIDIA Orin AGX, delivering 275 TOPS of AI performance to drive object recognition, task assignment, and group coordination. It is not designed to work alone: connected via WiFi, ALPHA can operate in synchronized fleets controlled by a central cloud system that distributes tasks based on shared camera input — a radically different approach from typical self-contained robots.

Get the Right Humanoid

Our Connect Service gives you a fixed-fee, unbiased shortcut to finding, testing, and choosing the right humanoid robot:

With 25% of recycling streams currently lost to contamination, ALPHA helps boost sorting purity and reduce error. In an industry with injury and fatality rates far above average, robots like ALPHA could make a measurable difference for worker safety. From lifting bins to sorting plastics, ALPHA steps in where humans shouldn’t have to — offering a solution that is safer, smarter, and ready for the circular economy.