Interview with Rob Knight — Building the World’s Most Dexterous Robot Hands

“Hands are the hardest part of the hardest challenge

– a game you can never fully complete.”

Rob Knight

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Rob Knight has spent two decades obsessing over robots, humanoids and robot hands. In this wide‑ranging video call with Humanoid.guide he explains why dexterous manipulation is the bottleneck for humanoids, how tendons still beat tiny gearboxes, and why he hopes robots will push humanity toward a post‑scarcity society.

Before the Interview:

A Chat on Printing and Robotics

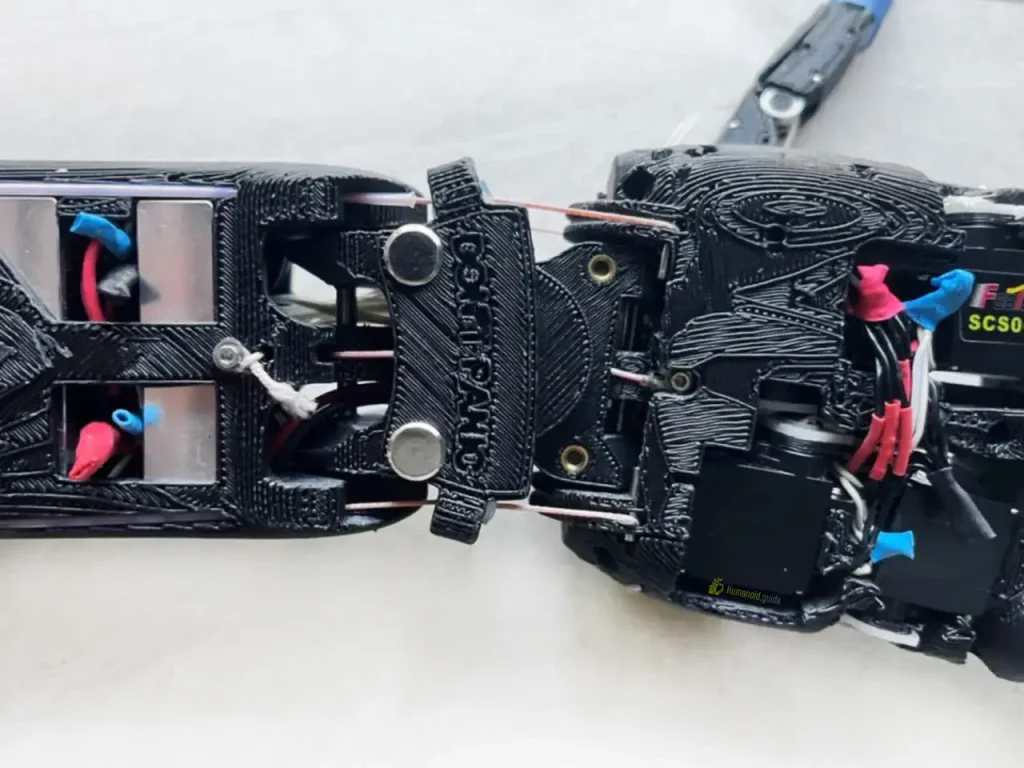

Humanoid.guide: How are you? I was supposed to turn on my amp when I turned on my webcam, but it didn’t happen. Rob: Oh, that’s technology for you. I’m good – just trying to get a print running. Humanoid.guide: Smart. Printing while you do other things is a good use of time. Rob: Indeed. I’ve just designed a deployable structure that’ll probably take three or four hours to print. Humanoid.guide: Are you printing it on the Bambu Labs, or something else? Rob: This one’s on an UP printer. I actually have a couple of rather old machines – UP Box-, those are pretty good actually and I use primarily for carbon‑fibre filament. It’s chopped‑strand. A lot of people use Markforged, but this setup is much cheaper. If you get the parameters right, the parts have incredibly high, almost uni‑directional strength. Humanoid.guide: I’ve been testing the new PPA‑CF blend. Have you tried that? Rob: Oh yes – PPA‑CF and PA‑CF-12 as well. They’re very impressive. Humanoid.guide: It seems to be around four times stronger than PLA. Rob: I’d say ten times. Bambu has test data online – especially on inter‑layer impact. I print 8 mm × 8 mm columns, 80 mm tall, in nylon, and I can’t break them by hand. I used to challenge people at trade shows – only two have ever managed it. It’s my favourite material. (Red.: Rob starts another print.) We use the Bambu for finer‑detail parts – the hands and wrist components – and the UP for the carbon‑fibre jobs. Rob: Okay – could you give me a quick bit of background? Humanoid.guide: Sure. Thanks for taking the time. I’m a semi‑nerd myself – three printers at home – and I got into humanoid robotics about eight years ago when I invested in a humanoid company. Before that I built and sold a smartphone company. I wanted to put part of the exit money into something new and exciting, and robotics felt like the next big thing. Rob: Norway has quite an ecosystem, doesn’t it? Humanoid.guide: ABB’s robot‑arm division traces back to Norway via an acquisition. There are a few Norwegian robotics successes; 1X is the main one right now. Rob: They’re now based out of San Jose, right – their new HQ? Humanoid.guide: Partly. They still have a site in Moss, Norway, but they’re definitely expanding rapidly in Silicon Valley.

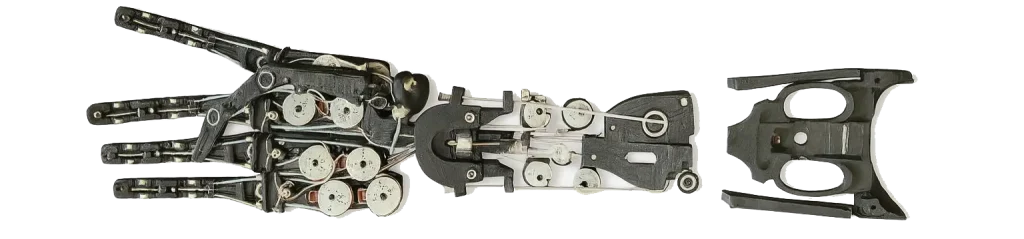

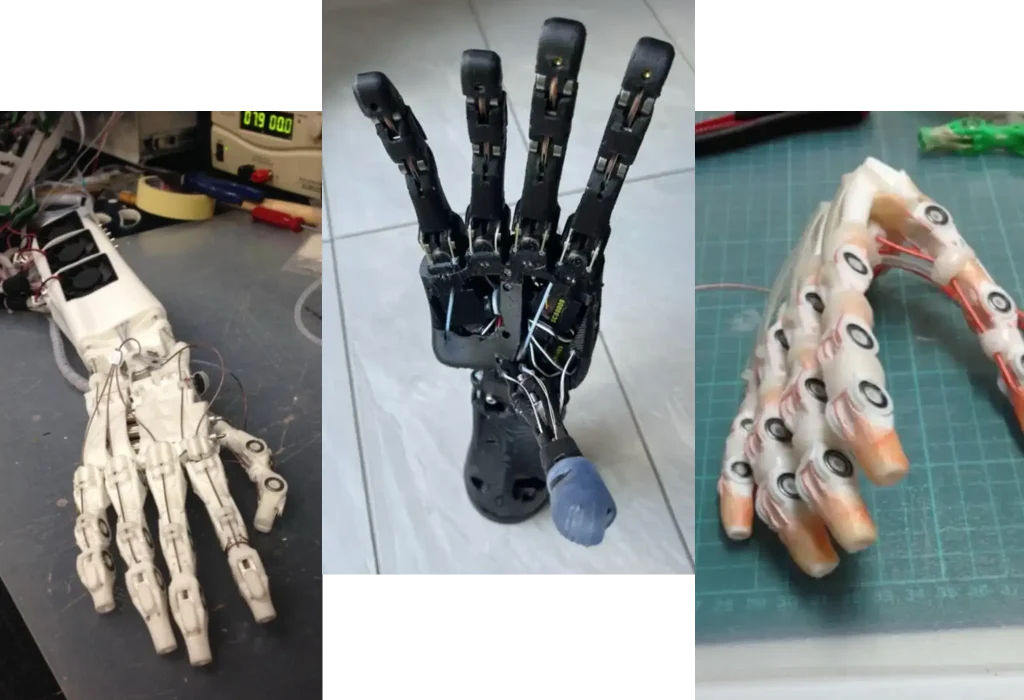

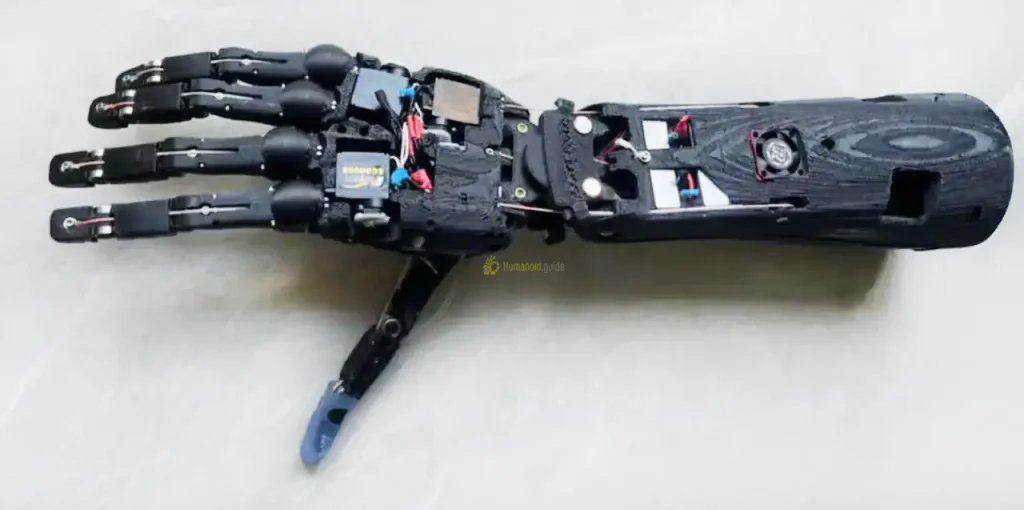

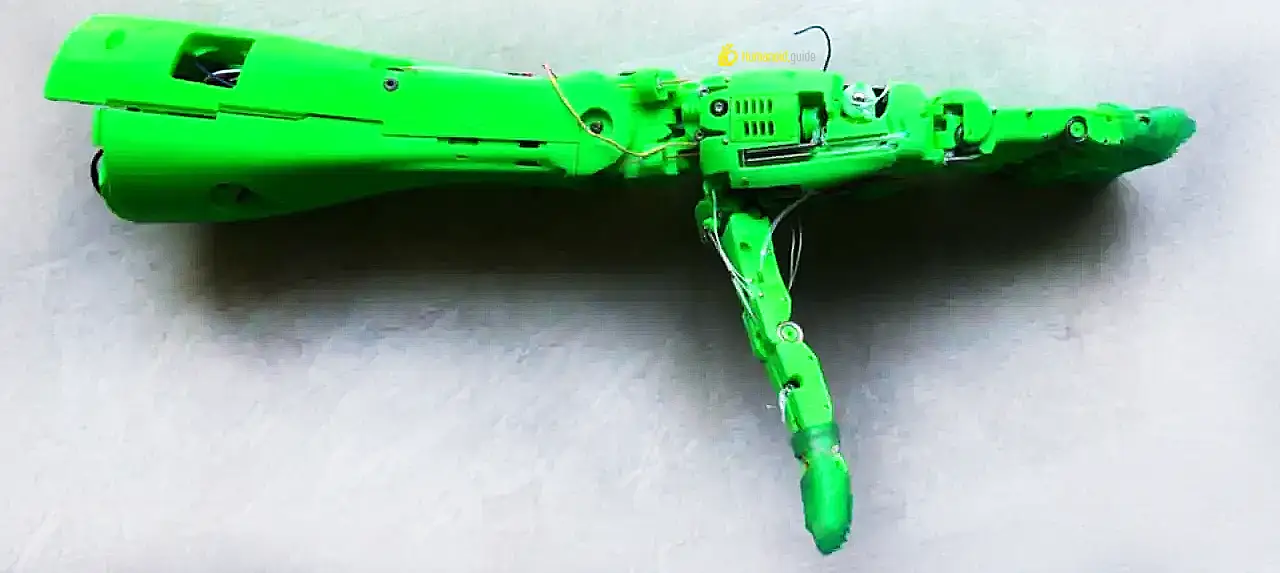

What are those projects i see behind you?

Rob: Happy to give you a tour. I’ve been at this a long time. These early models are the Anthropomimetic robots I built for ECCERobot around 2005 – hand‑made before affordable 3‑D printers existed. To the best of my knowledge – until Clone Robotics came along – they were the most anatomically realistic robots ever built: spinal discs, accurate scapula motion, the works. One finger is broken now; it’s getting old. Humanoid.guide: Tendon‑based, right? Rob: Yes. I advocated tendons for years, though I’ve moved away from them for standard robots. Long‑term I think we’ll come back to tendons – they have superior performance – but they’re a pain to assemble and maintain. Humanoid.guide: 1X still uses tendons, as you know. Rob: Yes. Humanoid.guide: They’re one of the few – maybe the only one right now. You mentioned Clone; they’re on pneumatics, correct? Rob: Clone uses a proprietary McKibben‑style muscle: a soft tube inside a braided sleeve that contracts when pressurised. They’re using pneumatics for now but want to switch to hydraulics for better power density. For the hands – like Tesla – they decided on tendons so the motors can sit in the forearm.

If you want to read more about robotic hands – download the Humanoid Robot Market Report 2026 here:

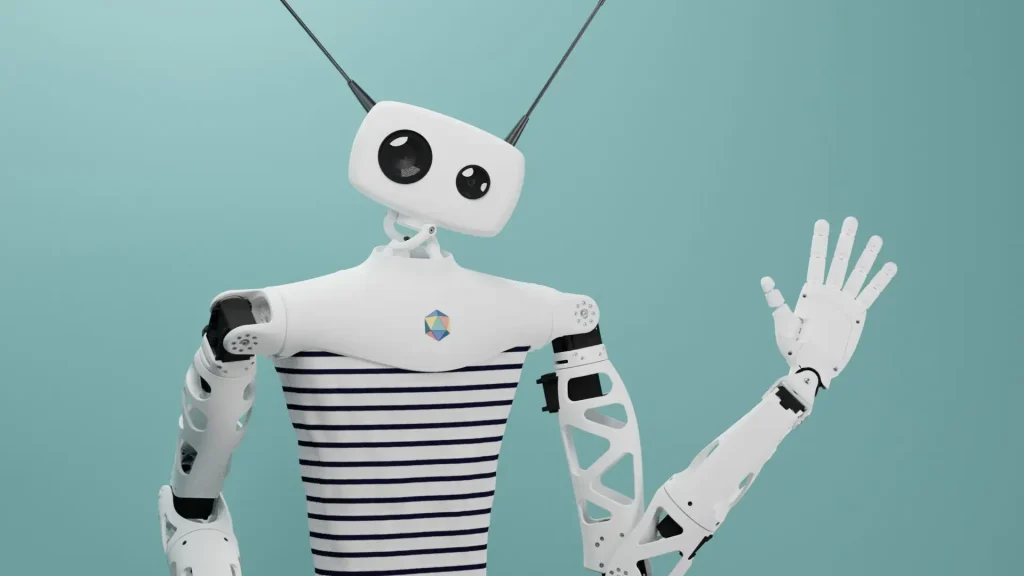

Most recently I built the SO-Arm and Hope Junior for Hugging Face. That project went completely the other way – ultra‑simple by design. Humanoid.guide: That’s with Pollen Robotics, right? Rob: Yes – Hugging Face acquired Pollen Robotics. I’m under contract with them. Humanoid.guide: You’re the one who made that small arm they released about a week ago? Rob: Exactly. They didn’t know I was doing it – I released a mini version on LinkedIn just for fun. The original arm was designed last year, but it’s gone viral, especially after the last hackathon – photos show literal piles of robot arms. That’s been my goal for 20 years: lots of robots. I talk a lot about the convergence of exponentials; it finally feels inevitable.

Humanoid.guide: So what’s your formal background?

Rob: I earned two degrees at the University of Cambridge, then a master’s at Essex. One year into a PhD I dropped out. Humanoid.guide: Not enough patience for a PhD? Rob: Partly, but the real reason was an EU FP7 loophole: the industrial partner in a project could be a brand‑new company. I was doing the PhD mainly to spin up a firm anyway, so I quit, created a company, and became the industrial partner on the CRONOS (Red: Conscious Robot Or Nearest Offer System) and ECCERobot (Red: Emerging Cognition in a Compliant Engineered Robot) projects. It took two years – rejected the first year, top‑rated the next with virtually the same proposal. That funding led to exotic robots and a seven‑year partnership with Maxon Motors. Back then robots never broke through; I’ve weathered one AI winter and several robot winters. Now the waves are overlapping – cheaper printing, motors, sensors – and at last weekend’s hackathon thousands of people were building robots.

If you want to read more about robotic hands – download the Humanoid Robot Market Report 2026 here:

Humanoid.guide: So you don’t expect another winter? Is the trend irreversible?

Rob: I’ve been wrong before, but I doubt we’ll see another. The AI genie won’t go back in the bottle, and demographics – ageing populations – drive adoption. Short of global catastrophe, by 2030 the need is acute. Some predict AGI within two years – if that happens, all bets are off. Humans think linearly while tech grows exponentially; analysts missed that with smartphones, too.

Humanoid.guide: You’ve recently focused on robotic hands

What drew you to concentrate on hands when you also build full humanoids? Rob: Funny you ask – the last full humanoid I did was Hope Junior; its hands were re‑worked by someone else. I’m fascinated by hands because they’re the hardest part of the hardest challenge – a game you can never fully complete.

Humanoid.guide: Why are hands so hard?

Rob: They’re the whole body system made smaller, denser and more complex. Many humanoid teams build everything else and then stall at the hands – they’re tougher than all the previous work combined.

Why are hands so hard? Rob: They’re the whole body system made smaller, denser and more complex. Many humanoid teams build everything else and then stall at the hands – they’re tougher than all the previous work combined.

Humanoid.guide: Why insist on human‑shaped hands? Rob: For a long time I thought the data argument was strongest: if a robot’s hand is like a human’s, you can replay human data directly. Now I’m working with people who show you can swap data sets arbitrarily, so that matters less. Still, matching the human form removes a layer of abstraction. The strongest argument may be psychological – how humans perceive and trust the machine. With a biped you know how it will fall or recover; with wheel‑balancing bots (think Segway accidents) you don’t. Put a human face and gestures on a robot and people treat it as a person. Trust will be vital when robots look after things that matter.

Humanoid.guide: So the psychological factor beats data or evolutionary optimisation?

Rob: Long‑term, yes. Robots you work with daily will probably stay human‑shaped, but high‑function, specialised machines may not. Star Wars is a fun example: everyone loves R2‑D2 and BB‑8 – clearly non‑humanoid – while C‑3PO is… annoying. It’s one of robotics’ trillion‑dollar questions. Humanoid.guide: Will a robot hand ever fully replace a human one – do everything we can do? Rob: Absolutely, given enough time. Mechanically, robots will surpass humans on every metric. Humanoid.guide: What blocks us right now? Rob: Look at quadrupeds: early models were clumsy because they used components from other industries. Today the parts – batteries, outrunners, sensors – are designed for quadrupeds and they do things humans can’t. Hands need that same bespoke supply chain plus flexible tactile skins; no prior industry needed that, so it doesn’t yet exist commercially. The technologies haven’t converged yet.

Humanoid.guide: In the next 5–10 years, could robot hands be stronger or more precise than ours?

Rob: Timeline makes it tricky, but engineering always wins. Metals don’t need to “grow”; power‑to‑weight can be far higher. Cars once had to drive behind a man with a red flag – now they out‑run any human. Cost‑effectiveness is the real question, not capability. Humanoid.guide: Biggest mistake or dead end you’ve hit when designing a hand? Rob: No dedicated hand simulator exists. Tools like Isaac Sim treat hands as an afterthought. Everything is slightly wrong until you build hardware, which is backwards: we guess, build an expensive prototype, then discover if it can do dexterous manipulation. We need a tool‑chain where you fully simulate, iterate, and then manufacture.

If you want to read more about robotic hands – download the Humanoid Robot Market Report 2026 here:

Humanoid.guide: Should robot hands differ from human ones – joint count, finger lengths?

Rob: I’ve experimented. My V1 hand had three finger lengths; V2 uses uniform lengths – easier manufacturing. You could give robots extreme ranges or heat‑proof metal fingertips for cooking robots. Specialised single‑task machines still make sense, but I foresee an “iPhone of hands” everyone recognises as the general‑purpose model.

Humanoid.guide: Today, what’s the main bottleneck – mechanics, controls, motors, sensors?

Rob: All of them, but especially integrated tactile sensing and a full simulation–design tool‑chain. Until those exist, reliable dexterous hands remain just out of reach. [excerpt ends]

Humanoid.guide: When designing a human‑like robotic hand, what’s the main challenge now? Mechanics, controls, motors, sensors – where’s the missing piece so it becomes just a software problem? Rob: Exactly – that’s the goal: reach the point where the hardware vanishes into the background and it’s “only” software. But today the bottlenecks are everywhere. You can 3‑D‑print frames, use bearings, high‑quality fishing‑line tendons, hobby servos – then you try to shoe‑horn it into Isaac Sim and it’s still a pain.

Humanoid.guide: Do we need fundamental research, or are all the building blocks here and it’s “just” engineering?

Rob: All the pieces exist in prototype form. I can design a self‑contained, dexterous unit – at research‑lab quantities and cost – but we can’t control it yet. The mechanical side is solvable; the simulation‑plus‑control side still lags. Humanoid.guide: How reliable are your current designs? Rob: Long‑term tests run for months without drift. V2 can be bought fully assembled yet user‑repairable. V3 will be plug‑in modules you swap and return. V4 will be fully industrial‑rated – but bulkier and boxier. V5 (someday) could use advanced polymers: mouldable bones with human‑like friction, liquid cooling, self‑healing skins. For scale you’d need to produce millions of hands per week to hit a billion robots in ten years.

Humanoid.guide: Engineering while ramping manufacturing seems risky.

Rob: Exactly. Companies like Figure.ai are impressive, but I’m not sure how they’ll overcome the scale challenges on their chosen path. Humanoid.guide: Side note – A company I am involved in bought the Inspire hand and tried to make it crawl like in the movie “The Thing”. After a few steps a finger snapped. Rob: Bought from Jacob Wu? The hand selling best now is the Psyonic prosthetic. More robots use that than amputees because it’s rugged and lasts.

If you want to read more about robotic hands – download the Humanoid Robot Market Report 2026 here:

Humanoid.guide: How far are we on touch sensitivity?

Can a robot already distinguish silk from sandpaper? Rob: Limited lab prototypes can, but no mature commercial product yet. You still need flexible tactile skins and integration with simulation. It’s likely a few years away – but stealth startups pop up all the time. With Isaac open‑sourced and big players entering (rumours say even Apple is exploring robots) the race is on. Humanoid.guide: Apple building a robot? Rob: Just rumours – remember Project Titan (self‑driving car) and its $10 billion burn. Robotics is fashionable; we’ll see. Personally I’m open‑source because I believe robots can steer humanity toward a post‑scarcity future. The alternative is slipping back into fascism or neo‑feudalism – unacceptable to me.

Humanoid.guide: About simulation and reinforcement learning (RL) for robot hands: will RL be as crucial as it is for walking and jumping?

Rob: Yes. Approaches that converge to 100 % success all involve RL. Two main pipelines: start with RL then layer conditional control or start with imitation learning and fine‑tune with RL. We do the latter. Look up the Berkeley work on sparse human‑in‑the‑loop RL – they hit 100 % success on complex tasks with grippers. Hands are tougher, but the same principles apply. Humanoid.guide: Harder because the hand interacts more richly with the world than a robot walking on a flat plane. Rob: Hands involve many more contact points than walking, which is why Isaac Sim – built for big robots on flat planes – still struggles with them. Yet once locomotion and perception mature, hands will be the primary bottleneck to dull‑dirty‑dangerous tasks. Without dexterous manipulation, the promise of robots reshaping civilisation can’t happen.

Humanoid.guide: The robot itself is almost just a means of transport for the hands?

Rob: In many cases, yes. Does it even need legs?A heavy wheeled base is cheaper and the batteries last five times longer. You’ll buy a glamorous legged concierge for your hotel lobby, but ten cheap wheeled cleaners for the toilets. Maybe legs get cheap eventually – but I doubt it. Humanoid.guide: Among today’s humanoid vendors some use tendons, some in‑hand actuators. Pros and cons? Rob: Two main metrics: packing density and finger strength.Direct‑drive / in‑hand motors – Current high‑torque micro‑actuators make the fingers huge. Classic example: the Allegro hand – popular but clumsy for tools. Prosthetic hands like Psyonic put motors in‑hand but only give six DoF, fine for amputees (limited neural channels). Power‑density isn’t there yet for full human dexterity and strength. Tendon drive – Keeps the motors in the forearm/torso, so you can match human DoF and keep weight low. Power‑to‑weight is everything: lighter means safer. Everyone shows off back‑flips, but real value is a robot you can lift out of a car boot like in Robot & Frank [film title].

“Power-to-weight is everything: lighter means safer.”

Power-to-weight is everything: lighter means safer. Small high‑power actuators are coming, but not yet. Until then tendons win despite material downsides. Humanoid.guide: 1X’s CEO [Bernt Øivind Børnich] harps on robot weight; moving motors inward helps. Rob: Exactly. Tendons “pipe” power mechanically. Downsides are mostly material. Open a chicken foot and feel how low‑friction biological tendons are – an order of magnitude better than synthetics.

Humanoid.guide: But ropes stretch; you need to tension them often?

Rob: Modern UHMWPE fishing line is designed for 100‑metre runs; over a 20 cm span stretch is tiny. Months‑long tests show minimal drift – just occasional recalibration, which AI can automate. Humanoid.guide: We still see tension drift every couple of weeks on working robots. Rob: Depends on load and routing. Digital spool adjustment helps. V4 will shift to engineering‑rated components. Humanoid.guide: Using rope for both agonist and antagonist means slack can develop? Rob: That’s why I use a passive spring extensor: you only tune one side. You lose some peak strength but avoid excessive internal tension. Full antagonistic tendon loops winding around shafts cause wear, heat and rope flattening – accelerated decay. Rob: Cable wear is a real issue. Early Boeing 747s used steel cables for the control surfaces; Boeing’s studies showed you need a minimum pulley diameter relative to cable thickness or the lifespan plummets. With small spools the diameter changes as the line wears, so tension drifts and the cable eventually fails. That’s why tendon paths should be hermetically sealed – ideally flooded with coolant – and kept clean.

Humanoid.guide: Could a tiny, high‑back‑drivable linear micro‑actuator in the palm solve the tendon problem?

Rob: I wish. I’ve talked with motor companies. Tiny planetaries, harmonic drives – none hit the power‑density target at human volume or cost. Even if you build one‑offs, pulley diameters still limit tendon routing. So, no: with current tech a palm‑filled actuator isn’t viable. Humanoid.guide: What about using brakes to hold loads instead of continuous motor torque? Rob: My metal‑spool hand can hold 80 kg by locking the gearbox, though it can’t lift that weight. Closing the loop with tactile sensors is better for most tasks. The “ideal” actuator simply doesn’t exist yet. Smart‑polymer muscles still lose arm‑wrestling contests to an eight‑year‑old girl in the famous DARPA challenge – electric motors remain king despite their flaws. Humanoid.guide: So you rely on external force sensors rather than back‑drivable motors? Rob: Exactly. To get required torque you need high‑reduction gearboxes, which kill transparency. Large QDD outrunners (120 mm+) work for humanoid elbows/hips, but the tech doesn’t scale to finger size. So we add tactile sensors instead.

If you want to read more about robotic hands – download the Humanoid Robot Market Report 2026 here:

Humanoid.guide: Fingernails seem trivial, but…

Rob: Not trivial at all!

Nails and the palm heel (“thenar eminence”) are crucial – opening packets, peeling labels, gripping pans. They’re often ignored, as is the role of the soft palm. Humanoid.guide: Your current prototypes use hard 3‑D‑printed plastics. How important are soft materials? Rob: Eventually vital. A 1950s prosthetic with an inflatable palm could hold a plane or hammer because the contour matched the object. Future hands will likely embed soft gel bladders with tactile arrays. Flexible, robust, low‑cost tactile skins remain the missing component, but it’s an engineering problem that will be solved once economically viable.

Humanoid.guide: How impactful will 3‑D printing be for volume production of robot hands and humanoids?

Rob: Absolutely essential right now because it lets us iterate fast. With open‑source releases anyone can download, tweak and remix a design – people already build double‑size versions of my hands or customise them for their own tasks. Cheap, precise manufacturing has been democratised. Humanoid.guide: Will 3‑D printing also handle mass production – and spare‑part logistics? Rob: Great for early stages and specialist variants, but once you’re aiming at 2 million hands a week you’ll switch to stamped steel or injection/blow‑moulded polymer – one unit per second. Agility Robotics tried to scale with printed parts and hit legal and supply snags. Scaling is inevitable, but timing matters. Humanoid.guide: Material trend – will designs move from aluminium to engineering plastics and carbon‑filled nylon? Rob: As we cut weight we can use “weaker” materials. Lightweight printed shells are already hollow and efficient. Eventually you might blow‑mould parts and back‑fill them with foam. It all depends on the operating envelope: if a robot must survive construction‑site abuse you still choose aluminium or steel; for a hotel concierge, carbon‑nylon is fine. Humanoid.guide: Blank‑sheet humanoid today – aluminium or carbon‑nylon? Rob: Depends on use‑case. I personally lean carbon‑nylon, but I’m designing for companies that prefer metal. The art is shrinking the design space quickly without fatal early assumptions. Humanoid.guide: Will we get a plug‑and‑play “iPhone of hands,” or will vendors build sealed, integrated hands? Rob: Likely both – an Apple‑like closed stack and a PC‑style modular ecosystem. Mark Raibert’s AI Institute explicitly aims to define interoperability standards so parts from multiple vendors just work. Humanoid.guide: After leaving Boston Dynamics, Marc is now mostly into research. How will he manage to create these standards? Rob: If anyone can shepherd standards, it’s him. Meanwhile I half‑expect Apple to drop a “Home Robot” that just works – and user convenience will drive adoption. Humanoid.guide: Technology also feeds back into lifestyle – commuting, schooling…

Rob: Exactly. Daily rush‑hour is collective madness.

Robots plus automation could free society from such inefficiencies – but we need cultural will, not just tech. Education is another relic: kids still learn for jobs that won’t exist in the not so distant future. Humanoid.guide: Do you foresee universal basic income? Rob: If we succeed, money itself may fade. Read Iain M. Banks’ Culture novels: people live for self‑improvement and helping others. That’s my long‑term blueprint – even if I won’t live to see it. If we succeed, the very concept of money may fade.

Humanoid.guide: Great place to end. Thanks for the insights! 🤩🤖

If you want to read more about robotic hands – download the Humanoid Robot Market Report 2026 here: