Boston Dynamics Atlas is getting smarter

Introduction

Boston Dynamics has stunned the world again, unveiling an electric version of its Atlas robot autonomously performing tasks in a factory setting. This demonstration of Atlas working without human guidance marks a potential inflection point in robotics, where humanoid robots move from experimental prototypes to practical tools capable of taking on human roles in industries like manufacturing. Could this be the beginning of robots creating tangible value in the workforce?

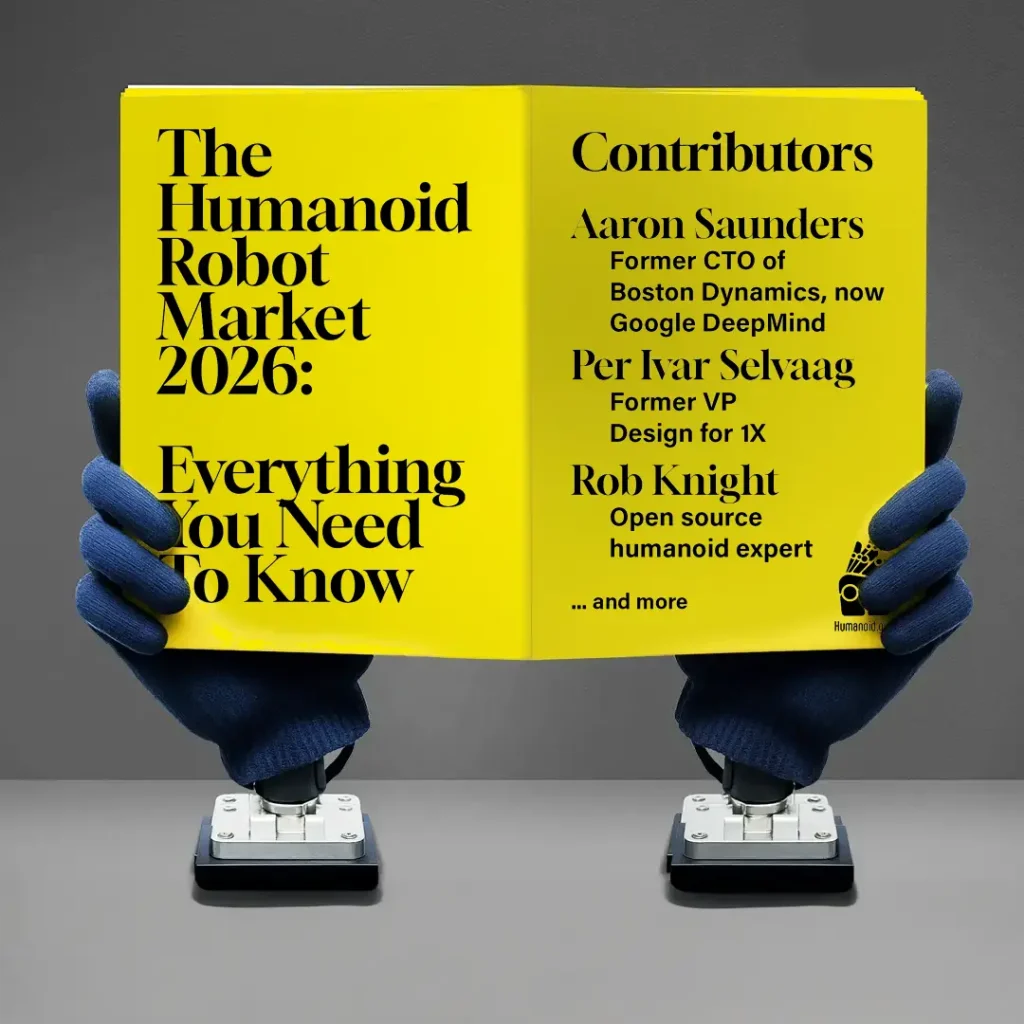

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Atlas’s Journey: From Stunts to Practical Skills

Initially famous for its athletic prowess, Atlas showed off what a bipedal robot could do in terms of agility, balance, and precision. But this new electric model has evolved beyond parkour tricks. In a recent video, Atlas navigates a busy factory environment, autonomously lifting and carrying items and interacting with equipment designed for human workers. This leap from performing stunts to practical, task-oriented work signals a transformation in Atlas’s purpose and the wider possibilities for humanoid robotics.

The Significance of Autonomous Humanoids in Factories

What sets this Atlas apart is its autonomy. Without any external commands, it navigates complex workspaces, lifting objects, avoiding obstacles, and adapting to its surroundings. For industries where manual labor has been essential, Atlas’s independence may represent a shift toward a future where humanoid robots collaborate or substitute in specific roles. The increasing presence of autonomous humanoids could address labor shortages, operational costs, and workplace safety—especially in manufacturing, logistics, and beyond.

Why Electric? Boston Dynamics’ Step Toward Sustainable Robotics

The switch from hydraulics to electric power for Atlas reflects Boston Dynamics’ focus on efficiency and sustainability. Electric power not only reduces emissions but also improves energy efficiency and minimizes noise—a crucial aspect for indoor industrial environments. For companies with eco-conscious goals, electric-powered robots offer an alignment with sustainable practices, supporting the shift toward green technology in manufacturing and other industries.

This step toward environmentally conscious robotics also has broader implications. By using electric power, robots like Atlas become viable in a wider range of applications, both indoors and outdoors. This aligns with modern manufacturing’s emphasis on reducing carbon footprints and achieving sustainability, making Atlas a symbol of the future in energy-efficient robotics.

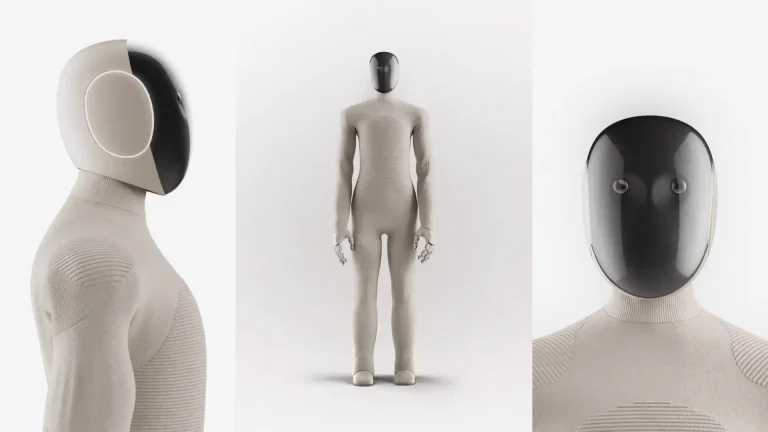

An Inflection Point: Humanoids as Real Contributors to the Workforce

For years, humanoid robots remained largely experimental, useful primarily in research and specialized demonstrations. However, the electric Atlas suggests we may finally be at the point where robots can create real value in work environments. Unlike other automated systems, humanoids are well-suited for spaces and tools designed for humans, allowing for smoother integration into existing workflows. This makes Atlas uniquely positioned to handle versatile tasks across different industries—a prospect that could reshape industrial labor.

Benefits and Challenges of Autonomous Humanoids

Integrating robots like Atlas into the workforce comes with several advantages:

- Higher Productivity: Robots can work continuously, which can improve output and reduce turnaround times.

- Enhanced Safety: Robots can undertake high-risk tasks like heavy lifting or working with toxic materials, reducing hazards for human workers.

- Long-term Savings: Although the initial investment may be steep, long-term savings through reduced labor costs and increased efficiency could offer substantial returns.

However, there are challenges to consider:

- Technical Refinement: While promising, Atlas and similar robots still need further development to manage unpredictable environments reliably.

- Job Implications: With robots taking on labor-intensive roles, there may be concerns about job displacement. Businesses will need to balance automation with retraining or reassigning employees for roles that complement robotic assistance.

- Maintenance Costs: While long-term benefits exist, maintaining and supporting robotic systems like Atlas may require specialized resources and personnel.

Broader Implications Beyond Factories

The electric Atlas’s abilities extend the potential of humanoid robots beyond factory settings. With further development, humanoids could play significant roles in areas like healthcare, performing repetitive tasks and freeing professionals for patient-focused care. In logistics, they could help manage last-mile delivery, optimizing supply chains.

While the conversation about job impacts is unavoidable, the future of humanoids like Atlas might ultimately involve human-robot collaboration. Robots could take on repetitive and high-risk tasks, while humans could focus on creative, strategic, or socially complex work. Together, this synergy could lead to more efficient, innovative industries.

Conclusion: A New Collaborative Future

Boston Dynamics’ new electric Atlas represents a leap in robotic capabilities, potentially opening a new chapter where humanoid robots genuinely contribute to industry. If successful, Atlas could become a pivotal partner in various fields, from factories to healthcare, shaping a new future of human-robot collaboration. This step is more than a technological achievement; it’s a glimpse into a world where humans and robots work side by side, each playing to their strengths, fostering a more productive and innovative society.

Maybe we are just months away from full time working Humanoid Robots…?

See our specifications of the Atlas Here: https://humanoid.guide/product/atlas/

Or visit Boston Dynamics product page: https://bostondynamics.com/atlas/