Airbus Tests UBTech Walker S2 Humanoid Robots in Aircraft Assembly

Airbus begins humanoid robot trials

Airbus has purchased humanoid robots from China based UBTech Robotics to evaluate their use in aircraft manufacturing environments. The company confirmed it is testing UBTech’s Walker S2 humanoid robot within its production operations, marking one of the most concrete industrial trials of humanoid robots in large scale aerospace manufacturing to date.

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

The deal, first reported by Forbes, involves a six figure purchase per robot and is focused on experimentation rather than immediate deployment on active assembly lines.

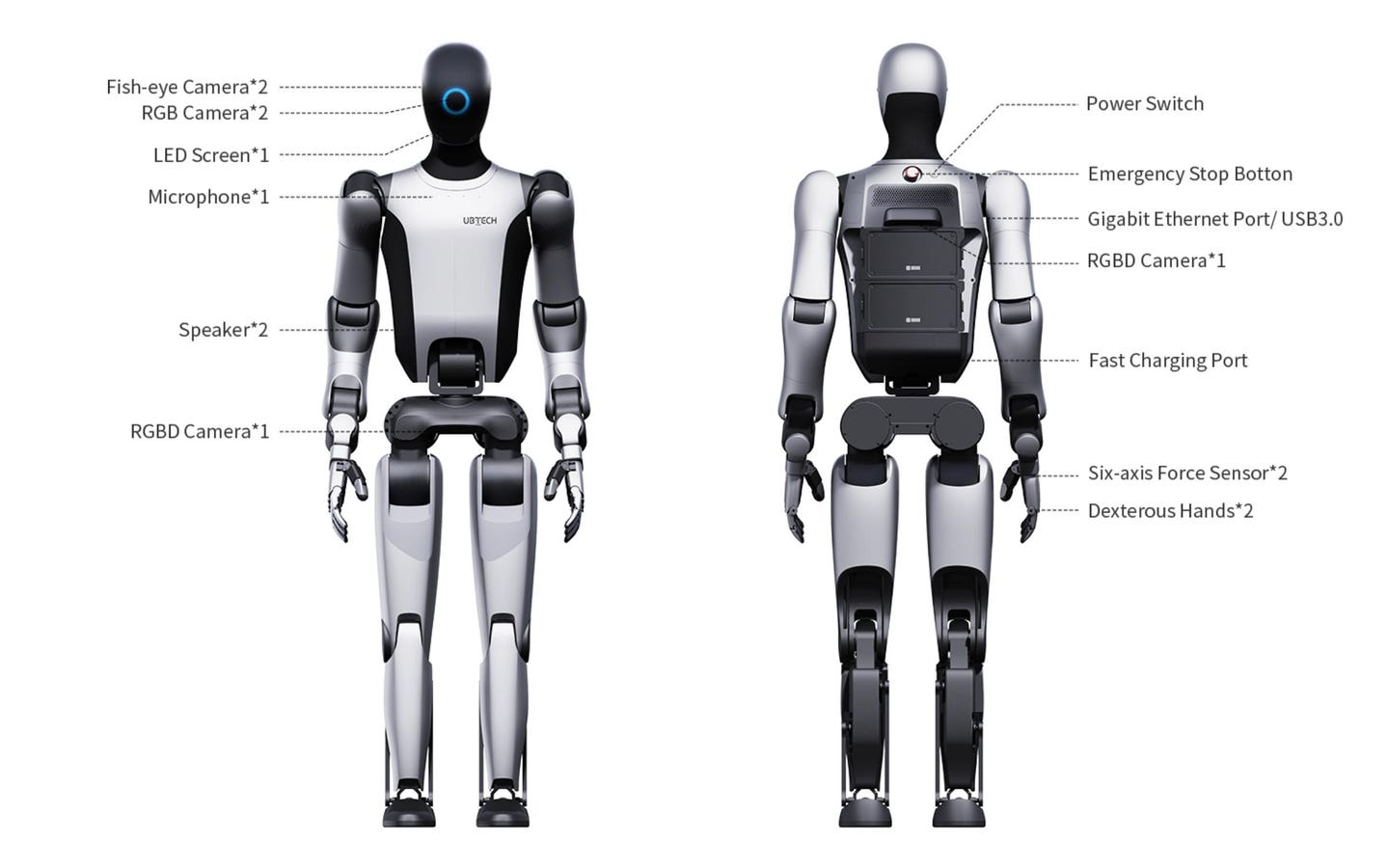

Walker S2 capabilities and design

The UBTech Walker S2 is a full size humanoid robot designed for structured indoor environments such as factories, laboratories, and commercial facilities. It features a bipedal locomotion system, articulated arms with dexterous hands, and onboard perception systems for navigation and object handling.

According to UBTech, the platform is intended to perform repetitive and ergonomically challenging tasks that are difficult to automate with fixed industrial robots. These include material handling, tool transport, and inspection oriented workflows that benefit from humanlike reach and mobility.

Why Airbus is exploring humanoids

Aircraft assembly involves a high mix of manual processes, constrained spaces, and frequent reconfiguration. Traditional industrial automation struggles in these environments, which is why aerospace manufacturing remains labor intensive compared with automotive production.

By testing humanoid robots, Airbus is assessing whether general purpose, mobile platforms could complement human workers in tasks such as parts logistics, fixture setup, and inspection support. The company has emphasized that the current effort is exploratory and focused on understanding technical limits, safety integration, and return on investment.

Implications for the humanoid robotics market

The Airbus purchase represents a meaningful signal for the humanoid robotics sector, which is increasingly targeting industrial use cases beyond demonstrations and pilot programs. While Walker S2 is not yet approved for safety critical production work, its evaluation inside a major aerospace manufacturer provides valuable feedback on reliability, maintainability, and human robot collaboration.

For humanoid robot developers, aerospace trials highlight both opportunity and challenge. Success depends not only on locomotion and manipulation, but also on integration with existing manufacturing systems, rigorous safety standards, and consistent uptime in demanding factory conditions.