Humanoid robots near mass production as Tesla targets 2026 launch

Humanoid robots are moving from lab prototypes toward early mass production, according to a new industry report from Digitimes. The shift reflects steady progress in artificial intelligence, perception, and motion control, alongside growing supply chain readiness for complex bipedal systems.

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

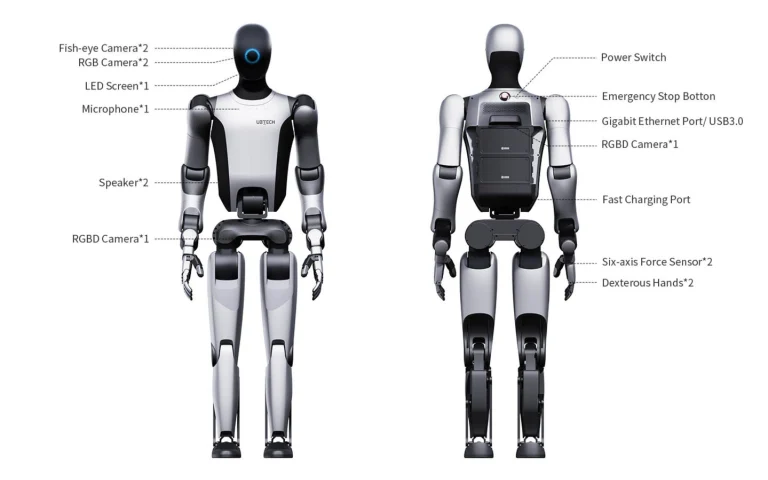

From concept demos to functional systems

The transition was visible at CES 2026, where many humanoid robots were shown performing live demonstrations rather than static displays. Vendors emphasized integrated perception stacks, improved balance control, and more reliable end effectors, signaling a focus on real task execution rather than form-only showcases.

Several platforms demonstrated longer continuous operation and smoother whole body motion, suggesting incremental but meaningful gains in actuator efficiency and control software. These improvements are critical for moving humanoids into pilot deployments in logistics, manufacturing support, and structured service environments.

Tesla sets a 2026 target

Tesla remains one of the most closely watched players in the sector. The company has indicated 2026 as a target year for launching its humanoid robot into initial production, aligning with broader industry expectations for limited commercial availability.

While detailed specifications and production volumes have not been finalized publicly, the timeline underscores confidence that core subsystems such as vision, manipulation, and autonomy are approaching levels suitable for controlled real world use.

Supply chain and manufacturing considerations

Digitimes notes increasing engagement from component suppliers across Asia, particularly in actuators, sensors, and precision gear systems designed specifically for humanoid form factors. These components differ from traditional industrial robot parts, requiring tighter integration and higher power density.

Manufacturers are also evaluating modular designs to reduce assembly complexity and support iterative upgrades, a strategy seen as essential for scaling humanoid production beyond pilot runs.

Early market outlook

Industry sources expect initial deployments to focus on environments where tasks are repetitive, structured, and closely supervised. Full autonomy in unstructured settings remains a longer term goal, but incremental commercial use is increasingly viewed as achievable within the next two years.

As more vendors move from prototypes to pre production units, 2026 is shaping up to be a pivotal year for testing whether humanoid robots can transition from promise to practical tools.