Zoomlion deploys humanoid robots to assemble excavators at scale

Humanoid robots move into heavy equipment manufacturing

Chinese construction equipment manufacturer Zoomlion has begun using humanoid robots on active production lines to assemble excavators, according to a report by Electrek. The company says the robots are already contributing to high throughput assembly, with a completed excavator rolling off the line roughly every six minutes.

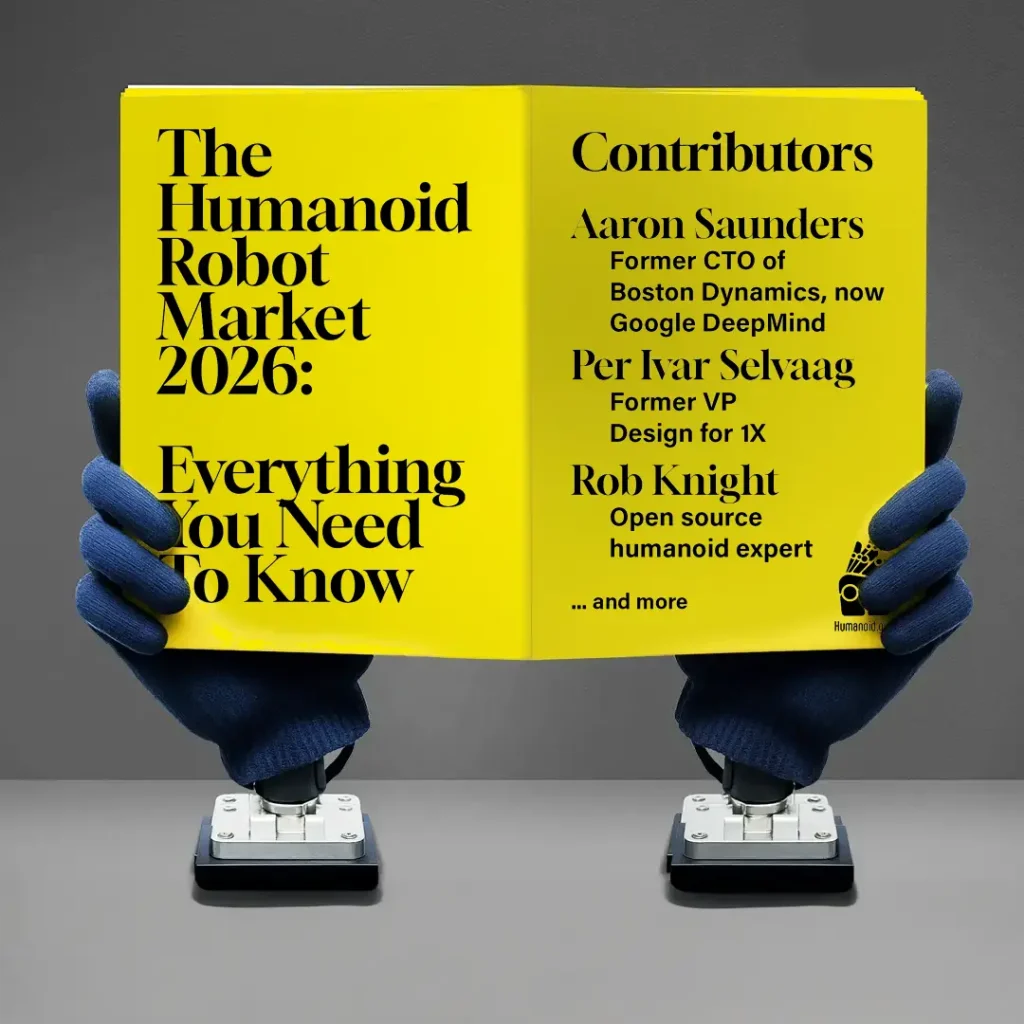

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Unlike pilot programs or lab demonstrations, the deployment is presented as a live manufacturing operation. Zoomlion frames humanoid robotics as part of what it calls a “third growth curve,” alongside electrification and digital manufacturing.

What the humanoid robots are doing

The humanoid systems are used for tasks that traditionally require human dexterity and mobility across a complex factory floor. These include parts handling, positioning, and assembly steps that are difficult to automate with fixed industrial arms alone.

By using a humanoid form factor, Zoomlion aims to reduce the need for custom tooling and reconfigured work cells when production changes. The robots operate within existing assembly environments designed around human workers.

Implications for industrial automation

The deployment highlights a practical use case for humanoid robots in heavy industry, where product size, variability, and mixed manual processes have limited conventional automation. For operators, the key value proposition is flexibility rather than raw speed.

- Ability to work in human oriented workspaces without major redesign

- Potential to reassign robots across tasks as production needs change

- Reduced reliance on specialized single purpose automation

While detailed specifications of the humanoid robots have not been disclosed, the reported production rate suggests close coordination with traditional automated systems rather than full end to end humanoid assembly.

Industry context

Zoomlion joins a small but growing list of manufacturers experimenting with humanoid robots in real production settings. Most current deployments remain limited in scope, but they provide early data on reliability, integration costs, and workforce impact.

For robotics practitioners and factory planners, the case underscores a shift from experimental humanoids toward targeted industrial roles where adaptability can offset higher system complexity.