Tesla says Optimus humanoid robot production will start slowly

Production expectations for Optimus

Tesla chief executive Elon Musk said initial production of the company’s Optimus humanoid robot will be extremely limited, with volumes increasing only gradually over time. The comments were made alongside updates on Tesla’s broader product roadmap, including its autonomous Cybercab vehicle.

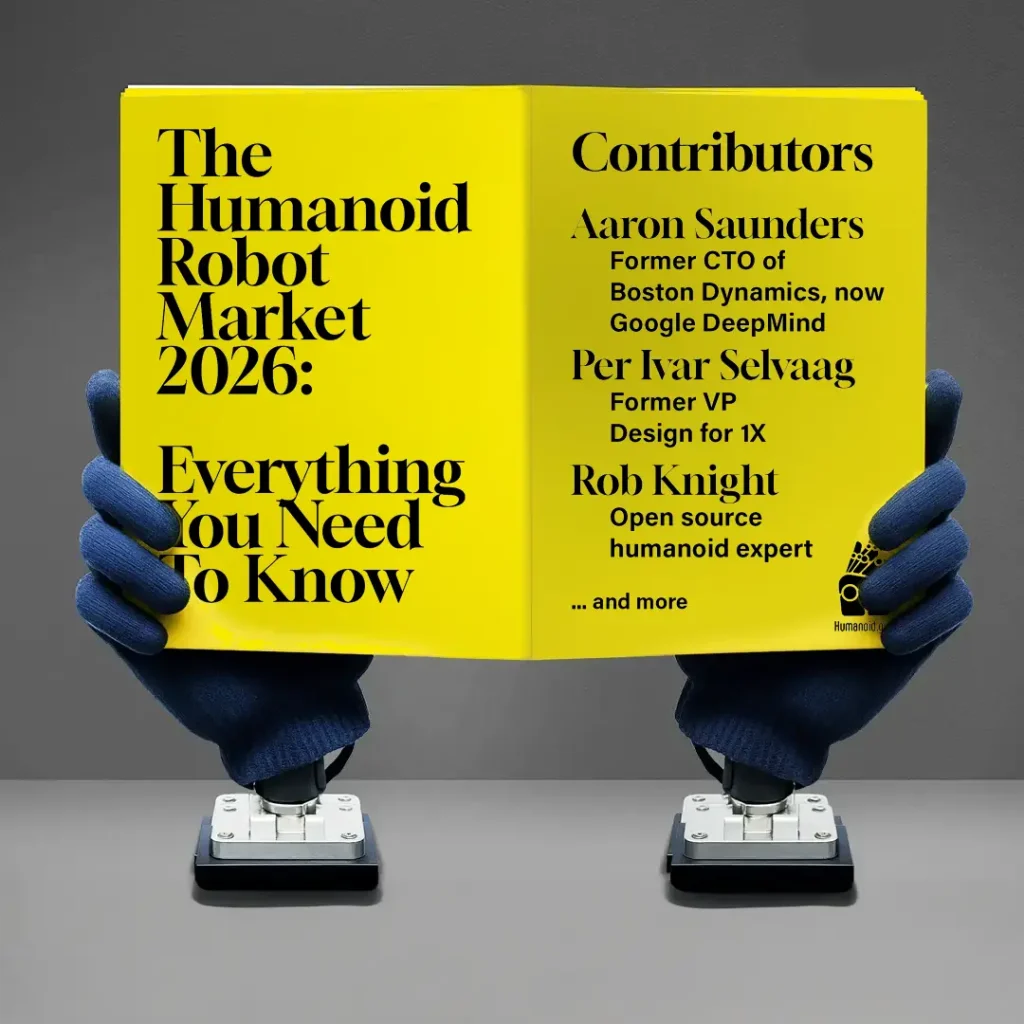

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

According to Musk, early output for Optimus is expected to be “agonizingly slow” as Tesla works through manufacturing constraints, supply chain readiness, and internal deployment milestones. No specific production targets or delivery timelines were disclosed.

Context within Tesla’s strategy

Optimus has been positioned by Tesla as a general purpose humanoid designed to perform repetitive or hazardous tasks in industrial and commercial environments. The company has previously demonstrated prototypes performing basic manipulation, walking, and warehouse style tasks, with early units reportedly intended for use inside Tesla facilities.

The cautious production outlook suggests that Optimus remains in a pre commercial scaling phase. For practitioners, this indicates that near term access to the platform outside Tesla is unlikely, and that capability validation will continue largely through internal use.

Implications for the humanoid robotics market

Tesla’s comments reflect a broader reality across humanoid robotics, where moving from demonstrations to reliable, repeatable manufacturing remains a major challenge. Slow initial output is common as companies refine actuators, control systems, safety validation, and assembly processes.

For system integrators and enterprise buyers tracking humanoid adoption, the update reinforces that meaningful deployment volumes will depend on sustained progress in manufacturing scale, not just software capability.

The original report was published by Channel NewsAsia.