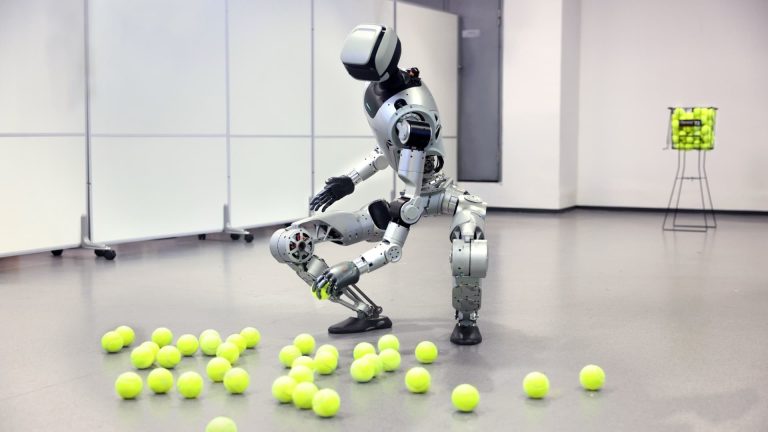

Humanoid robots move from labs to early workplace pilots globally

Humanoid robots begin limited workplace deployments

Humanoid robots are starting to appear in real workplaces as pilot systems rather than laboratory prototypes, according to a recent industry report cited by TechRadar. The shift is driven by persistent labor shortages, especially in roles that are physically demanding, repetitive, or difficult to staff consistently.

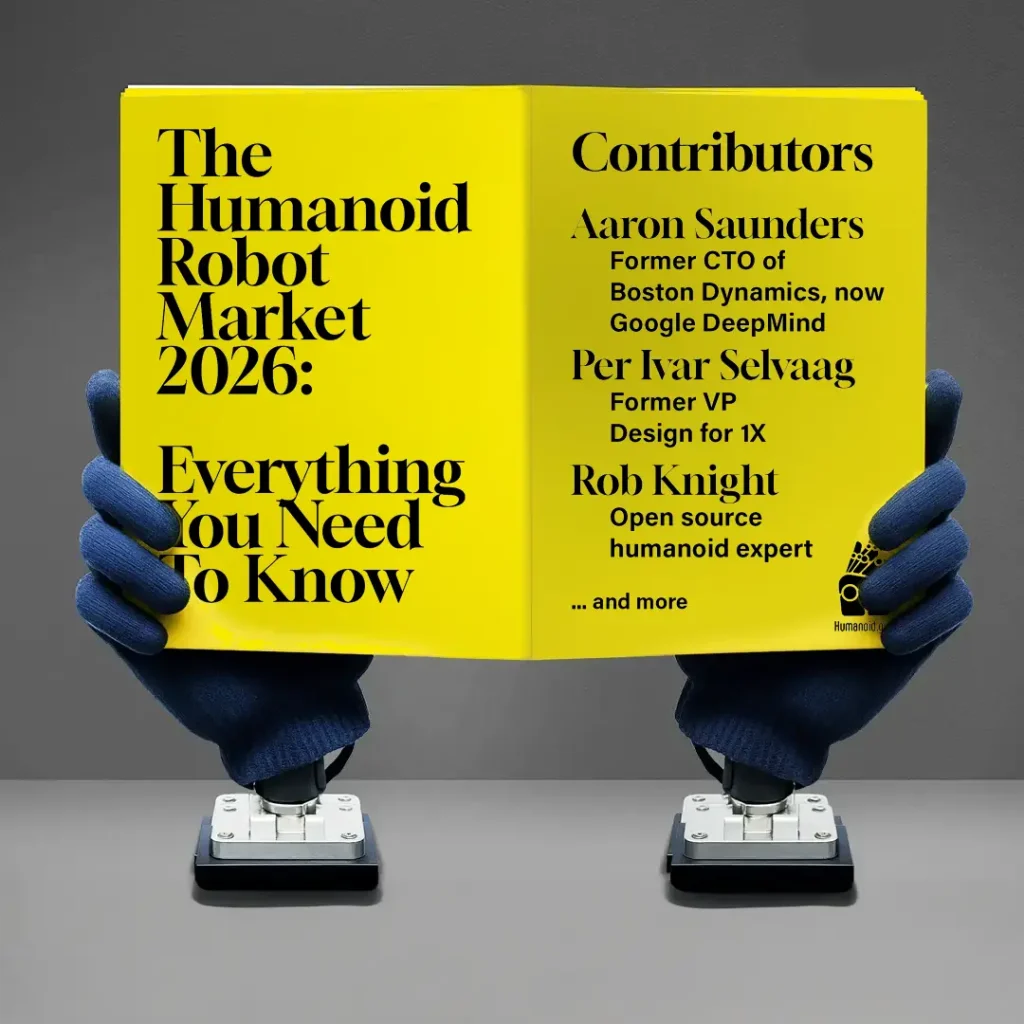

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

Featuring insights from

Aaron Saunders, Former CTO of

Boston Dynamics,

now Google DeepMind

2026 Humanoid Robot Market Report

160 pages of exclusive insight from global robotics experts – uncover funding trends, technology challenges, leading manufacturers, supply chain shifts, and surveys and forecasts on future humanoid applications.

These early deployments remain small in scale and are typically supervised. Most are designed to test feasibility in logistics, light manufacturing support, warehousing, and service tasks where humanlike form factors provide advantages over fixed automation.

Economic and technical drivers

The report highlights three main factors behind growing interest in humanoid systems. Hardware costs are declining as actuators, sensors, and compute platforms mature. Perception and manipulation capabilities have improved, allowing robots to operate in semi structured environments. At the same time, demographic trends and workforce shortages are increasing pressure on employers to explore alternatives.

China is identified as a leading producer of humanoid robots, supported by domestic manufacturing capacity and state backed investment. However, development activity remains global, with companies in North America, Europe, and Asia pursuing different approaches to bipedal locomotion, mobile manipulation, and safety control.

From pilots to production remains uncertain

Despite growing visibility, the path from pilot projects to broad adoption is not guaranteed. Key challenges include system reliability, maintenance costs, integration with existing workflows, and meeting safety requirements for close human robot interaction.

Decision makers are also focused on return on investment. Many current deployments are exploratory, intended to gather operational data rather than replace human workers at scale. As a result, humanoid robots are being evaluated as complementary systems rather than direct substitutes.

Implications for industrial operators

For operators and system integrators, the near term opportunity lies in controlled trials that define where humanoid form factors provide measurable value. Successful use cases are likely to involve tasks that benefit from humanlike reach and mobility but do not require full human level dexterity.

The report concludes that humanoid robots are no longer confined to research labs, but their transition into routine industrial use will depend on sustained technical progress and clear economic justification.